You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Newsworthy Science

- Thread starter Birdjaguar

- Start date

tjs282

Stone \ Cold / Fish

How viable is it?

Chemicals and aircraft parts manufacturer Honeywell International announced this week that it’s come up with a new way to turn low-grade plastic waste into oil that’s high enough quality to be fed into a refinery.

Sounds very much like another variant on this theme:I didn't see anything in the press release about making oil, only about recycling plastic in a better way. I don't know if the article's author knows something I don't, or if he is making that part up.

https://en.wikipedia.org/wiki/Thermal_depolymerization

If so, the technique isn't new (and can be used on just about any high-carbon organic-polymer waste-stream).

About 15(?) years back, there was actually a test-plant running in the US, converting a local meat-processing plant's offal into gas+oil -- until an allegedly 'grassroots' protest got it shut down.

Berzerker

Deity

https://phys.org/news/2022-02-tilting-earth-crust-ancient-megafloods.html

I did not know that, an ice dam need not break to cause a flood. The water can make it behave like a lift gate and when enough water passes underneath the weight of the ice overcomes the water pressure from the remaining reservoir and resettles blocking the water until more ice melted into the lake.

Now what got me confused was the ice sheets began melting 20kya so how could a lobe of an ice sheet block a river if its receding? I guess the meltwater grew into a lake that ran up against an existing lobe of the ice sheet.

During the height of the last ice age, vast ice sheets covered much of North America. They began to melt after about 20,000 years ago, and the Missoula megafloods occurred between 18,000 and 15,500 years ago. Pico's team studied how the changing weight of the ice sheets during this period would have tilted the topography of eastern Washington, changing how much water would flow into different channels during the floods.

Glacial Lake Missoula formed in western Montana when a lobe of the Cordilleran ice sheet dammed the Clark Fork valley in the Idaho panhandle and melt water built up behind the dam. Eventually the water got so deep that the ice dam began to float, resulting in a glacial outburst flood. After enough water had been released, the ice dam resettled and the lake refilled. This process is thought to have been repeated dozens of times over a period of several thousand years.

I did not know that, an ice dam need not break to cause a flood. The water can make it behave like a lift gate and when enough water passes underneath the weight of the ice overcomes the water pressure from the remaining reservoir and resettles blocking the water until more ice melted into the lake.

Now what got me confused was the ice sheets began melting 20kya so how could a lobe of an ice sheet block a river if its receding? I guess the meltwater grew into a lake that ran up against an existing lobe of the ice sheet.

Ice sheets do not recede evenly or at the same rate everywhere.Now what got me confused was the ice sheets began melting 20kya so how could a lobe of an ice sheet block a river if its receding? I guess the meltwater grew into a lake that ran up against an existing lobe of the ice sheet

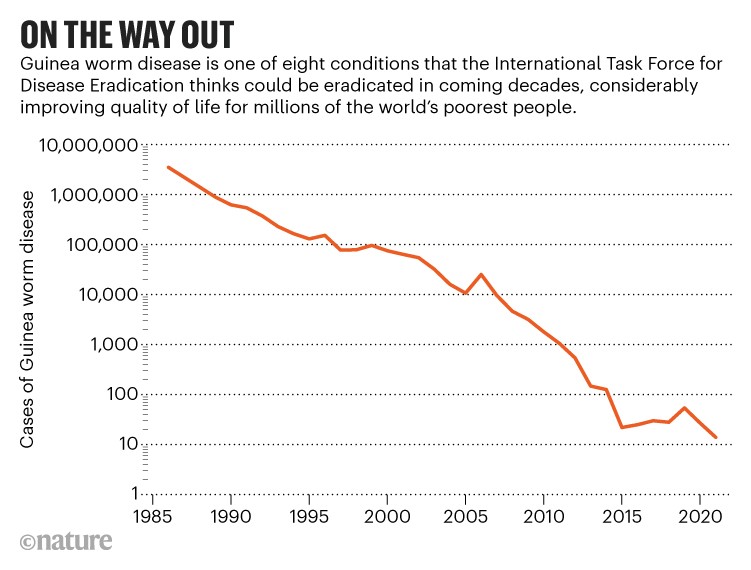

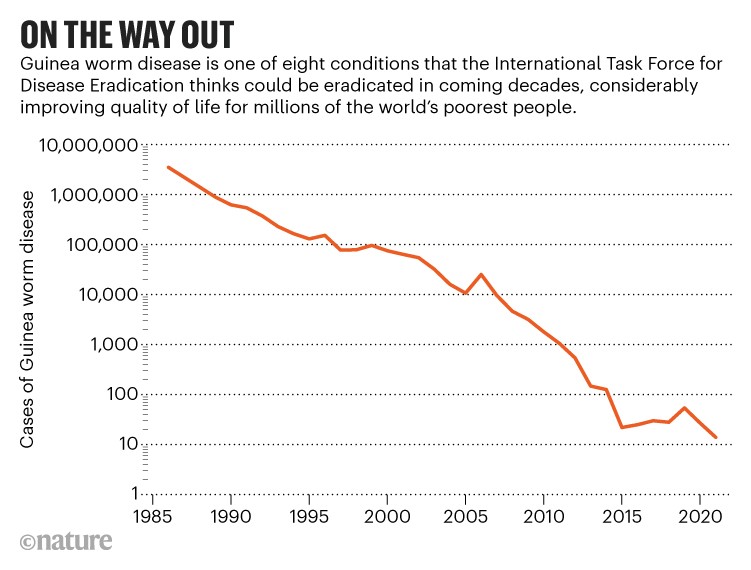

Another disease approaches eradication

So far we have only managed smallpox in humans and rinderpest in cows. Polio is getting close, with only four wild cases reported last year (there were also 597 vaccine derived cases). The latest news is that there were only 14 cases of Guinea worm in humans last year:

So far we have only managed smallpox in humans and rinderpest in cows. Polio is getting close, with only four wild cases reported last year (there were also 597 vaccine derived cases). The latest news is that there were only 14 cases of Guinea worm in humans last year:

Only 14 cases of infection with Guinea worm — a parasite that causes painful skin lesions — were reported in humans in 2021.

This is the lowest tally ever for an infection that, as recently as the 1980s, was found in more than 20 countries and infected 3.5 million people a year. However, a remaining reservoir for the parasite in animals means eradication could be a while off, if indeed it is possible, say some scientists.

“It’s pretty amazing,” says Adam Weiss, director of the Guinea Worm Eradication Program of the Carter Center, which is headquartered in Atlanta, Georgia. The centre announced the numbers in late January. “Fourteen people on a planet of almost eight billion. It’s mind-bending to think about.”

The reduction — nearly a 50% drop compared with the 27 cases reported in 2020 — is the result of a near 40-year effort by international organizations and national governments to rid the world of Guinea worm.

This progress is “remarkable”, says Julie Swann, a disease modeller at North Carolina State University in Raleigh — especially given that there is no recognized treatment or vaccine for the parasite. Instead, eradication campaigns have focused on preventing transmission, she says.

People and some animals, including cats, dogs and baboons, become infected with Guinea worm by drinking water that is contaminated with its larvae. After spending a year growing inside the host, the parasite — which can be up to one metre long — pushes through the skin of its host and waits to come into contact with water to release its larvae. The worm’s escape is painful and can last for up to six weeks, sometimes preventing people from working or even walking.

But the recognizable nature of Guinea worm disease also makes the parasite easy to detect. In Chad, where 7 of the 14 cases were reported last year, field agents create a network to track contaminated water sources, says Philippe Tchindebet Ouakou, the coordinator of the nation’s Guinea Worm Eradication Program, who is based in N’Djamena. They then prevent people from drinking the contaminated water and use pesticides to disinfect it.

But Swann isn’t entirely convinced that eradication is possible: she says that it’s hard to control diseases that have animal reservoirs, pointing out that there were 790 reported cases of Guinea worm infection in dogs in Chad alone last year.

This is the lowest tally ever for an infection that, as recently as the 1980s, was found in more than 20 countries and infected 3.5 million people a year. However, a remaining reservoir for the parasite in animals means eradication could be a while off, if indeed it is possible, say some scientists.

“It’s pretty amazing,” says Adam Weiss, director of the Guinea Worm Eradication Program of the Carter Center, which is headquartered in Atlanta, Georgia. The centre announced the numbers in late January. “Fourteen people on a planet of almost eight billion. It’s mind-bending to think about.”

The reduction — nearly a 50% drop compared with the 27 cases reported in 2020 — is the result of a near 40-year effort by international organizations and national governments to rid the world of Guinea worm.

This progress is “remarkable”, says Julie Swann, a disease modeller at North Carolina State University in Raleigh — especially given that there is no recognized treatment or vaccine for the parasite. Instead, eradication campaigns have focused on preventing transmission, she says.

People and some animals, including cats, dogs and baboons, become infected with Guinea worm by drinking water that is contaminated with its larvae. After spending a year growing inside the host, the parasite — which can be up to one metre long — pushes through the skin of its host and waits to come into contact with water to release its larvae. The worm’s escape is painful and can last for up to six weeks, sometimes preventing people from working or even walking.

But the recognizable nature of Guinea worm disease also makes the parasite easy to detect. In Chad, where 7 of the 14 cases were reported last year, field agents create a network to track contaminated water sources, says Philippe Tchindebet Ouakou, the coordinator of the nation’s Guinea Worm Eradication Program, who is based in N’Djamena. They then prevent people from drinking the contaminated water and use pesticides to disinfect it.

But Swann isn’t entirely convinced that eradication is possible: she says that it’s hard to control diseases that have animal reservoirs, pointing out that there were 790 reported cases of Guinea worm infection in dogs in Chad alone last year.

Last edited:

Broken_Erika

Play with me.

New Zealand: Scientists discover rare baby ghost shark

New Zealand scientists have discovered a rare baby ghost shark, a little-known species of fish that lives in the shadowy depths of the ocean.

https://www.bbc.com/news/world-asia-60386066

New Zealand scientists have discovered a rare baby ghost shark, a little-known species of fish that lives in the shadowy depths of the ocean.

https://www.bbc.com/news/world-asia-60386066

Umbilical cord blood used to cure HIV for the first time

The first woman, and only the third person, has been cured of HIV. This was done with stem cells derived from umbilical cord blood as a treatment for acute myeloid leukaemia.

The first woman, and only the third person, has been cured of HIV. This was done with stem cells derived from umbilical cord blood as a treatment for acute myeloid leukaemia.

Since receiving the cord blood, the middle-aged woman of mixed race has been in remission and free of HIV for 14 months, without the need for potent treatments known as antiretroviral therapy. The donor was naturally resistant to the virus that causes AIDS.

The two prior cases occurred in males who had received adult stem cells more frequently used in bone marrow transplants.

This new approach may make the treatment available to more people, according to researchers.

The case is part of a wider study led by the University of California, Los Angeles and Johns Hopkins University in Baltimore that follows 25 people with HIV who undergo transplants with stem cells for the treatment of cancer and other serious conditions.

Patients in the trial first undergo chemotherapy to kill off the cancerous immune cells and then receive transplant stem cells from individuals with a specific genetic mutation in which they lack receptors used by the virus to infect cells.

Lewin said that while bone marrow transplants are not a viable strategy to cure most people living with HIV, the report “confirms that a cure for HIV is possible and further strengthens using gene therapy as a viable strategy for an HIV cure”.

Writeup Conference abstractThe two prior cases occurred in males who had received adult stem cells more frequently used in bone marrow transplants.

This new approach may make the treatment available to more people, according to researchers.

The case is part of a wider study led by the University of California, Los Angeles and Johns Hopkins University in Baltimore that follows 25 people with HIV who undergo transplants with stem cells for the treatment of cancer and other serious conditions.

Patients in the trial first undergo chemotherapy to kill off the cancerous immune cells and then receive transplant stem cells from individuals with a specific genetic mutation in which they lack receptors used by the virus to infect cells.

Lewin said that while bone marrow transplants are not a viable strategy to cure most people living with HIV, the report “confirms that a cure for HIV is possible and further strengthens using gene therapy as a viable strategy for an HIV cure”.

EnglishEdward

Deity

Well that is good news of a sort.

Microbes convert industrial waste gases into commodity chemicals

The ability to convert waste gases from steel mills into commodity chemicals could make Clostridium autoethanogenum bacteria an industrial champion

Humans have exploited microbes for thousands of years to make products like alcohol, cheese, and yogurt. But industrial-scale biotechnology didn’t really take off until the beginning of the 1900s, when, for example, chemist Chaim Weizmann engineered several species of Clostridium bacteria to convert starches and sugars into acetone, an essential ingredient for making cordite, a smokeless alternative to gunpowder. (Weizmann’s success was key to the Allied victory in World War I and gained him fame; a Zionist politician as well as a chemist, Weizmann eventually became Israel’s first president in 1949.) But the rise of the petroleum industry in the 1950s and ’60s gave chemical manufactures cheaper starting materials for dozens of commodity chemicals, relegating most microbes to the industrial waste bin.

But not all. Today, yeast and Escherichia coli are widely used to produce a range of commodity chemicals, including ethanol for fuel and compounds used to make pharmaceuticals and plastics. But these industrial workhorses come with their own environmental footprint, because the sugars and starches they ferment come from crops like corn and sugarcane. By 2026, corn grown to make ethanol in the United States will take up to 19% of the nation’s farmland.

Now, synthetic biologists are pushing to grow microbes on a more environmentally friendly diet, using waste gases produced from industry, garbage dumps, and crop production, says Michael Köpke, a synthetic biologist at LanzaTech, a biotech company. In the 1990s, researchers engineered Clostridium autoethanogenum (C. auto), a bacterium originally enriched from rabbit feces, to produce ethanol from hydrogen gas and carbon monoxide (CO). Since then, researchers have slowly improved the ethanol yield and commercialized the process. In June 2018, LanzaTech opened the first production plant that uses the bacterium to make ethanol from a steel mill’s waste gas (a mix of mostly CO, carbon dioxide, and hydrogen gas), which would otherwise be vented into the atmosphere. The company now uses this technology to make some 90,000 tons of ethanol per year.

Jewett, Köpke, and their colleagues used a multistep strategy to coax C. auto into churning out acetone and isopropanol (IPA), a colorless liquid found in disinfectants and cleaners. They started with a collection of 272 sugar-eating Clostridium strains maintained by retired South African microbiologist David T. Jones, one of Weizmann’s last postdoctoral assistants. The research team broke apart the bacterial cells and mined them for enzymes that appeared to play a role in acetone biosynthesis. They sequenced the genes for 30 of these enzymes and inserted combinations of them into C. auto via gene-delivery vehicles called plasmids. Separately, the researchers engineered C. auto’s metabolism to prevent carbon and hydrogen building blocks from making other unwanted chemicals. Ultimately, Jewett, Köpke, and their colleagues generated and screened 247 genetic variants of the bacteria to find the best chemical producers. The result, they report today in Nature Biotechnology, is are C. auto strains that continuously convert steel waste gases into enough acetone and IPA to make them viable candidates for large-scale commercial production.

Jewett expects the same process could make the bacteria produce a variety of other chemicals, such as butanol, used in varnishes, and propanediol, found in cosmetics. Scown adds that the novel synthetic biology techniques could also help transform other recalcitrant microbes into industrial workhorses. “We’re just scratching the surface in terms of the [microbial] hosts that might be viable in the future,” she says.

The advance could also open the door to engineering microbes capable of feeding on other waste gases, such as those produced by municipal solid waste and agricultural debris. And if, like C. auto, these microbes use more carbon in making their products than is released into the atmosphere, industrial chemical production may someday transform from a greenhouse gas rogue into a champion.

But not all. Today, yeast and Escherichia coli are widely used to produce a range of commodity chemicals, including ethanol for fuel and compounds used to make pharmaceuticals and plastics. But these industrial workhorses come with their own environmental footprint, because the sugars and starches they ferment come from crops like corn and sugarcane. By 2026, corn grown to make ethanol in the United States will take up to 19% of the nation’s farmland.

Now, synthetic biologists are pushing to grow microbes on a more environmentally friendly diet, using waste gases produced from industry, garbage dumps, and crop production, says Michael Köpke, a synthetic biologist at LanzaTech, a biotech company. In the 1990s, researchers engineered Clostridium autoethanogenum (C. auto), a bacterium originally enriched from rabbit feces, to produce ethanol from hydrogen gas and carbon monoxide (CO). Since then, researchers have slowly improved the ethanol yield and commercialized the process. In June 2018, LanzaTech opened the first production plant that uses the bacterium to make ethanol from a steel mill’s waste gas (a mix of mostly CO, carbon dioxide, and hydrogen gas), which would otherwise be vented into the atmosphere. The company now uses this technology to make some 90,000 tons of ethanol per year.

Jewett, Köpke, and their colleagues used a multistep strategy to coax C. auto into churning out acetone and isopropanol (IPA), a colorless liquid found in disinfectants and cleaners. They started with a collection of 272 sugar-eating Clostridium strains maintained by retired South African microbiologist David T. Jones, one of Weizmann’s last postdoctoral assistants. The research team broke apart the bacterial cells and mined them for enzymes that appeared to play a role in acetone biosynthesis. They sequenced the genes for 30 of these enzymes and inserted combinations of them into C. auto via gene-delivery vehicles called plasmids. Separately, the researchers engineered C. auto’s metabolism to prevent carbon and hydrogen building blocks from making other unwanted chemicals. Ultimately, Jewett, Köpke, and their colleagues generated and screened 247 genetic variants of the bacteria to find the best chemical producers. The result, they report today in Nature Biotechnology, is are C. auto strains that continuously convert steel waste gases into enough acetone and IPA to make them viable candidates for large-scale commercial production.

Jewett expects the same process could make the bacteria produce a variety of other chemicals, such as butanol, used in varnishes, and propanediol, found in cosmetics. Scown adds that the novel synthetic biology techniques could also help transform other recalcitrant microbes into industrial workhorses. “We’re just scratching the surface in terms of the [microbial] hosts that might be viable in the future,” she says.

The advance could also open the door to engineering microbes capable of feeding on other waste gases, such as those produced by municipal solid waste and agricultural debris. And if, like C. auto, these microbes use more carbon in making their products than is released into the atmosphere, industrial chemical production may someday transform from a greenhouse gas rogue into a champion.

The ability to convert waste gases from steel mills into commodity chemicals could make Clostridium autoethanogenum bacteria an industrial champion

There's also work going on to make it produce butanol for plastics, and even longer chain alcohols (in a consortium with another bug, IIRC). But the industrial scale application is where it gets really interesting, and I don't think anyone is actually there yet.

Archaeologists discover 9,000-year-old shrine in Jordanian desert

A team of Jordanian and French archaeologists says it found a nearly 9,000-year-old shrine at a remote Neolithic site in Jordan’s eastern desert.

The ritual complex was found in a Neolithic campsite near large structures known as “desert kites”, or mass traps, that are believed to have been used to corral wild gazelles for slaughter.

Such traps consist of two or more long stone walls that converge towards an enclosure and can be found scattered across the deserts of the Middle East.

Within the shrine were two carved standing stones bearing anthropomorphic figures, one accompanied by a representation of the “desert kite”, as well as an altar, hearth, marine shells and miniature model of the gazelle trap.

The researchers said in a statement on Tuesday that the shrine “sheds an entire new light on the symbolism, artistic expression as well as spiritual culture of these hitherto unknown Neolithic populations”.

The proximity of the site to the traps suggests the inhabitants were specialised hunters and that the traps were “the centre of their cultural, economic and even symbolic life in this marginal zone,” the statement said.

It really seems that even the inhospitable bits of the middle east were the cradle of civilization.The ritual complex was found in a Neolithic campsite near large structures known as “desert kites”, or mass traps, that are believed to have been used to corral wild gazelles for slaughter.

Such traps consist of two or more long stone walls that converge towards an enclosure and can be found scattered across the deserts of the Middle East.

Within the shrine were two carved standing stones bearing anthropomorphic figures, one accompanied by a representation of the “desert kite”, as well as an altar, hearth, marine shells and miniature model of the gazelle trap.

The researchers said in a statement on Tuesday that the shrine “sheds an entire new light on the symbolism, artistic expression as well as spiritual culture of these hitherto unknown Neolithic populations”.

The proximity of the site to the traps suggests the inhabitants were specialised hunters and that the traps were “the centre of their cultural, economic and even symbolic life in this marginal zone,” the statement said.

I guess the daily hate may be playing it up a bit, but it looks like an interesting study.Not sure if the conclusion is sound, but interesting:

View attachment 621086

Then again maybe you have to calculate safe warp travel at that point ^_^

Here, we present continuous electroencephalography (EEG) recording from a dying human brain, obtained from an 87-year-old patient undergoing cardiac arrest after traumatic subdural hematoma.

Albeit the influence of neuronal injury and swelling, our data provide the first evidence from the dying human brain in a non-experimental, real-life acute care clinical setting and advocate that the human brain may possess the capability to generate coordinated activity during the near-death period.

The spectral analysis revealed a surge in absolute gamma power after suppression of neuronal activity in both hemispheres, followed by a marked decrease after cardiac arrest.

Given that cross-coupling between alpha and gamma activity is involved in cognitive processes and memory recall in healthy subjects, it is intriguing to speculate that such activity could support a last “recall of life” that may take place in the near-death state.

Albeit the influence of neuronal injury and swelling, our data provide the first evidence from the dying human brain in a non-experimental, real-life acute care clinical setting and advocate that the human brain may possess the capability to generate coordinated activity during the near-death period.

The spectral analysis revealed a surge in absolute gamma power after suppression of neuronal activity in both hemispheres, followed by a marked decrease after cardiac arrest.

Given that cross-coupling between alpha and gamma activity is involved in cognitive processes and memory recall in healthy subjects, it is intriguing to speculate that such activity could support a last “recall of life” that may take place in the near-death state.

Ferocitus

Deity

Fascinating hypothesis stemming from some beautiful scientific detective work.

The Mesozoic terminated in boreal spring

Abstract

The Cretaceous–Palaeogene mass extinction around 66 million years ago was triggered by the Chicxulub

asteroid impact on the present-day Yucatán Peninsula1,2. This event caused the highly selective

extinction that eliminated about 76% of species3,4, including all non-avian dinosaurs, pterosaurs,

ammonites, rudists and most marine reptiles. The timing of the impact and its aftermath have been

studied mainly on millennial timescales, leaving the season of the impact unconstrained. Here, by

studying fishes that died on the day the Mesozoic era ended, we demonstrate that the impact that

caused the Cretaceous–Palaeogene mass extinction took place during boreal spring. Osteohistology

together with stable isotope records of exceptionally preserved perichondral and dermal bones in

acipenseriform fishes from the Tanis impact-induced seiche deposits5 reveal annual cyclicity across

the final years of the Cretaceous period. Annual life cycles, including seasonal timing and duration

of reproduction, feeding, hibernation and aestivation, vary strongly across latest Cretaceous

biotic clades. We postulate that the timing of the Chicxulub impact in boreal spring and austral

autumn was a major influence on selective biotic survival across the Cretaceous–Palaeogene boundary.

https://www.nature.com/articles/s41586-022-04446-1

The Mesozoic terminated in boreal spring

Abstract

The Cretaceous–Palaeogene mass extinction around 66 million years ago was triggered by the Chicxulub

asteroid impact on the present-day Yucatán Peninsula1,2. This event caused the highly selective

extinction that eliminated about 76% of species3,4, including all non-avian dinosaurs, pterosaurs,

ammonites, rudists and most marine reptiles. The timing of the impact and its aftermath have been

studied mainly on millennial timescales, leaving the season of the impact unconstrained. Here, by

studying fishes that died on the day the Mesozoic era ended, we demonstrate that the impact that

caused the Cretaceous–Palaeogene mass extinction took place during boreal spring. Osteohistology

together with stable isotope records of exceptionally preserved perichondral and dermal bones in

acipenseriform fishes from the Tanis impact-induced seiche deposits5 reveal annual cyclicity across

the final years of the Cretaceous period. Annual life cycles, including seasonal timing and duration

of reproduction, feeding, hibernation and aestivation, vary strongly across latest Cretaceous

biotic clades. We postulate that the timing of the Chicxulub impact in boreal spring and austral

autumn was a major influence on selective biotic survival across the Cretaceous–Palaeogene boundary.

https://www.nature.com/articles/s41586-022-04446-1

And the summary:

Nice link.

Seasonal timing of the Chicxulub impact in boreal spring and austral autumn will aid in further calibrating evolutionary models exploring the selectivity of the K–Pg extinction and the asymmetry in extinction and recovery patterns between the two hemispheres. Decoupling short- and long-term effects of the bolide impact on the K–Pg mass extinction will also aid in identifying extinction risks and modes of ecological deterioration caused by the forthcoming global climate change. The uniquely constrained Tanis site5 offers valuable proxies for reconstructing the environmental, climatological and biological conditions that prevailed locally when the Mesozoic ended.

Nice link.

Ferocitus

Deity

It is a beautiful work. But, IMO, they overstate their conclusions a bit.And the summary:

Nice link.

It's still a kind of "opening hypothesis", and not a particularly strong one until they collect a lot more data.

Nonetheless, to even attempt to to say "Spring 66 million years ago...." is a grand effort.

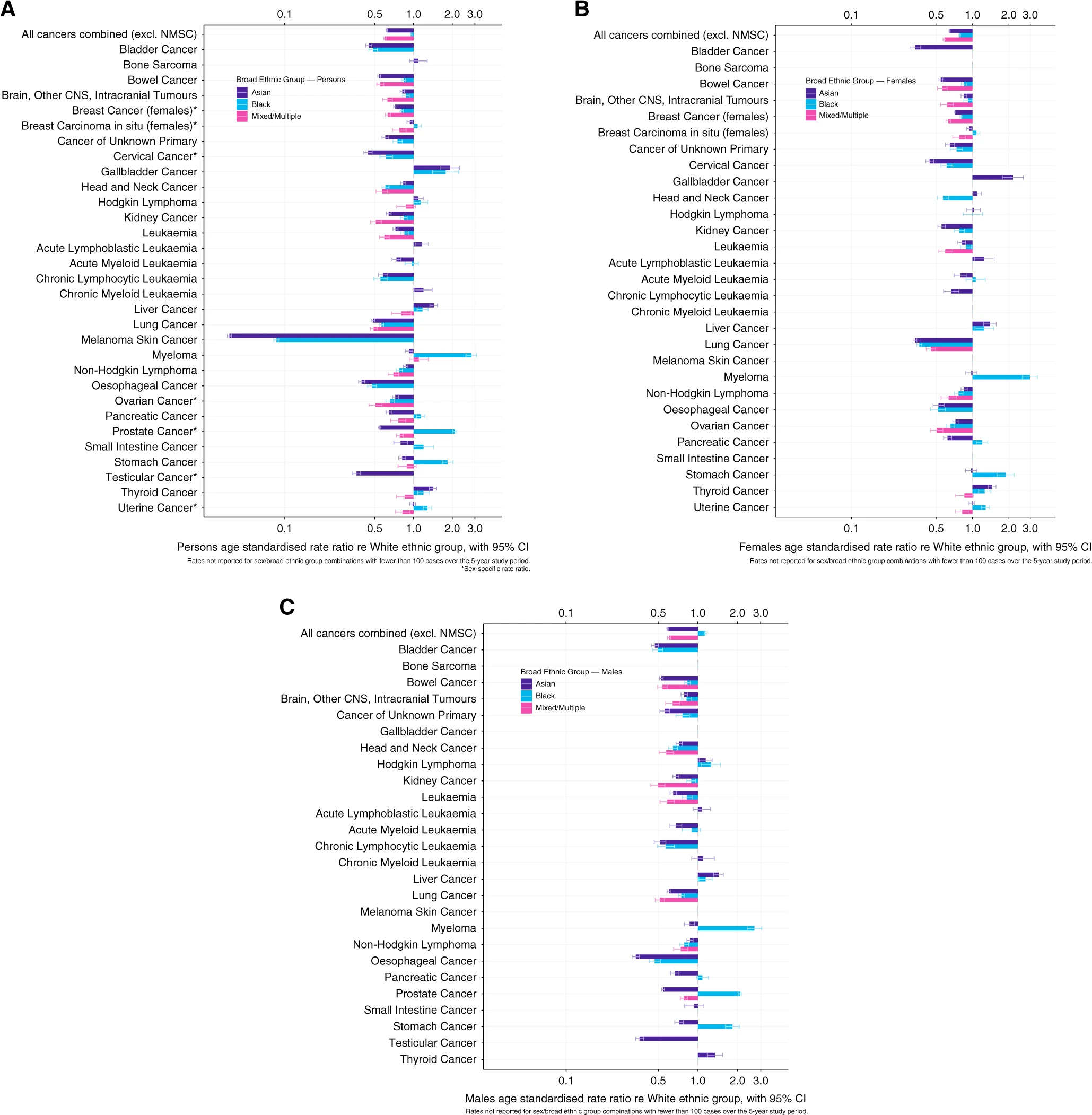

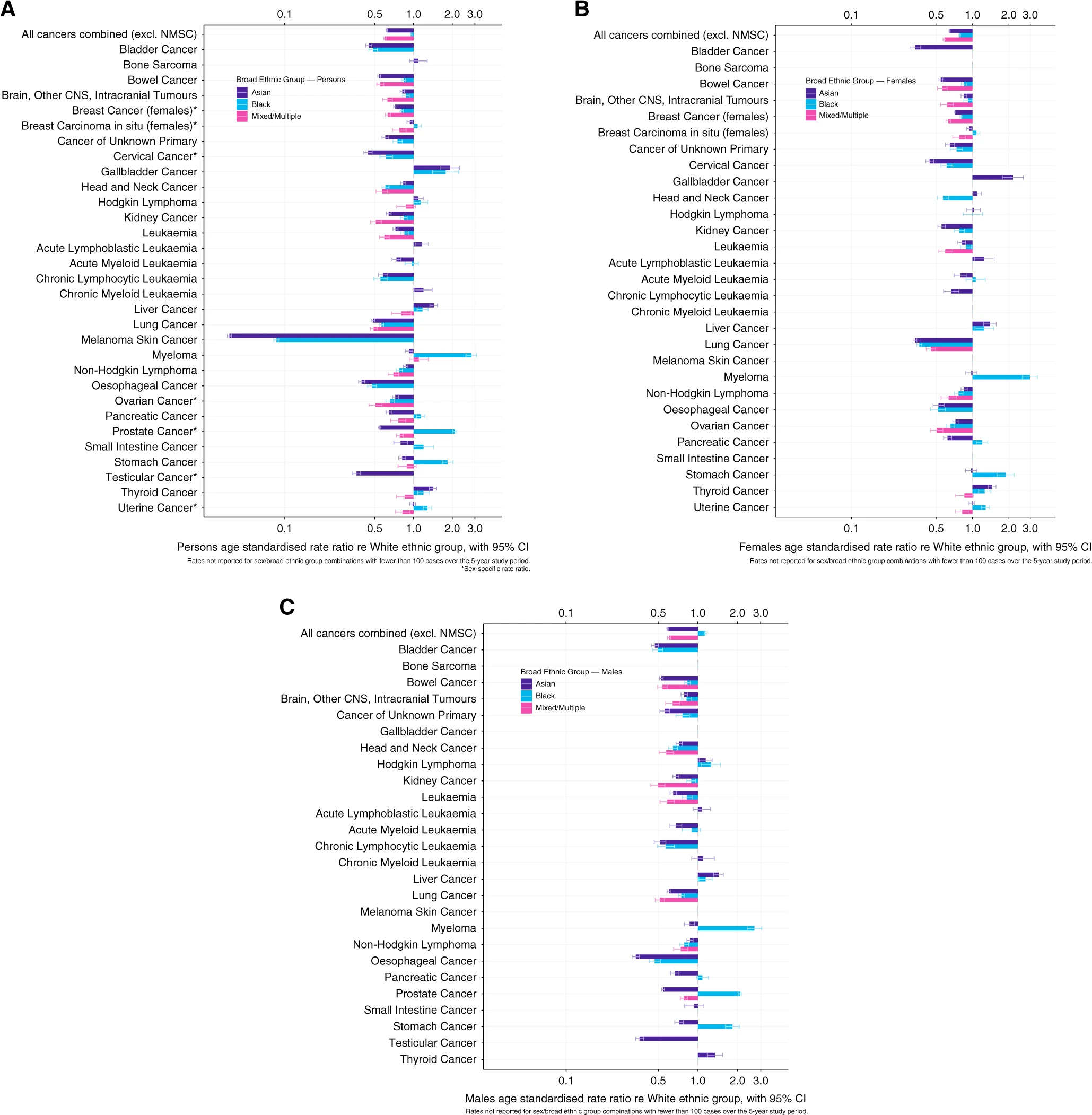

White people at much higher risk of most cancers in England, study finds

*Sex-specific rate ratio. Rate ratios of age-standardised incidence rates for persons (A), females (B) and males (C), by cancer site, for Asian, Black and Mixed/Multiple ethnic groups with reference to the White ethnic group.

Paper Beeb writeup

People of non-White minority ethnicity in England generally have lower cancer risk than the White population, though there are a number of notable exceptions. These results should galvanise efforts to better understand the reasons for this variation, and the possible impact on cancer services, patient experiences and outcomes.

Incidence rates for most cancer sites and ethnic group and sex combinations were lower in non-White minority ethnic groups compared with the corresponding White group, with particularly low rate ratios (below 0.5) for melanoma skin cancer and some smoking-related cancers (lung, bladder and oesophageal cancers). Exceptions included prostate cancer (2.1 times higher in males of Black ethnicity), myeloma (2.7–3.0 times higher in people of Black ethnicity), several gastrointestinal cancers (1.1–1.9 times higher in people of Black ethnicity, 1.4–2.2 times higher in people of Asian ethnicity), Hodgkin lymphoma (1.1 times higher in males of Asian ethnicity, 1.3 times higher in males of Black ethnicity) and thyroid cancers (1.4 times higher in people of Asian ethnicity, 1.2 times higher in people of Black ethnicity).

Skin cancer is more common because white-skinned people are more likely to burn and cause damage to their skin in the sun.

But black people are more likely to develop stomach and liver cancers.

Previous studies suggest there is a genetic explanation for black men being twice as likely to get prostate cancer than white men, and three times as likely to develop blood cancer (myeloma).

Cancer types linked to infections, such as hepatitis, are more common among people belonging to some ethnic minorities and this could be why Asian people are more likely to develop liver cancer.

Other reasons for the variations in cancer rates between ethnic groups include access to:

Incidence rates for most cancer sites and ethnic group and sex combinations were lower in non-White minority ethnic groups compared with the corresponding White group, with particularly low rate ratios (below 0.5) for melanoma skin cancer and some smoking-related cancers (lung, bladder and oesophageal cancers). Exceptions included prostate cancer (2.1 times higher in males of Black ethnicity), myeloma (2.7–3.0 times higher in people of Black ethnicity), several gastrointestinal cancers (1.1–1.9 times higher in people of Black ethnicity, 1.4–2.2 times higher in people of Asian ethnicity), Hodgkin lymphoma (1.1 times higher in males of Asian ethnicity, 1.3 times higher in males of Black ethnicity) and thyroid cancers (1.4 times higher in people of Asian ethnicity, 1.2 times higher in people of Black ethnicity).

Skin cancer is more common because white-skinned people are more likely to burn and cause damage to their skin in the sun.

But black people are more likely to develop stomach and liver cancers.

Previous studies suggest there is a genetic explanation for black men being twice as likely to get prostate cancer than white men, and three times as likely to develop blood cancer (myeloma).

Cancer types linked to infections, such as hepatitis, are more common among people belonging to some ethnic minorities and this could be why Asian people are more likely to develop liver cancer.

Other reasons for the variations in cancer rates between ethnic groups include access to:

- screening

- vaccines such as that the one against human papillomavirus (HPV), which protects against cervical cancer

- support to maintain a healthy lifestyle

*Sex-specific rate ratio. Rate ratios of age-standardised incidence rates for persons (A), females (B) and males (C), by cancer site, for Asian, Black and Mixed/Multiple ethnic groups with reference to the White ethnic group.

Paper Beeb writeup

Interesting. My first thought was that it could be the access to screening, but they addressed it. And given that the rates for some are higher, and that they're lower for the most obvious one, I think this is all valid and interesting.

.

.